Wooden Patterns

We are making Wooden Patterns from different types of Material like,

1. Teak Wood.

2. Ply Wood.

3. Dry Wood.

4. Card Board.

The largest Size Pattern we made -

The Largest Casting Produced from our Pattern -

Frequent Orders of Major Customers

Main Frame Body Pattern

- Made for Power Plant Sector to produce Main Frame Body Casting from Steel Grade Material.

- Casting Weight - 8000 Kgs.

- Base Material of Pattern - TEAK WOOD.

- Size of Pattern - 2500 x 2000 x 950 mm.

- Lead time of Manufacturing - 5 Weeks

Pattern for Globe Valve

- Made for Valve Manufacturer to produce Ball Valve Body Casting from Cast Iron Grade Material.

- Casting Weight - 450 Kgs.

- Base Material of Pattern - TEAK WOOD.

- Size of Pattern - 1100 x 800 x 500 mm.

- Lead time of Manufacturing - 1 Week

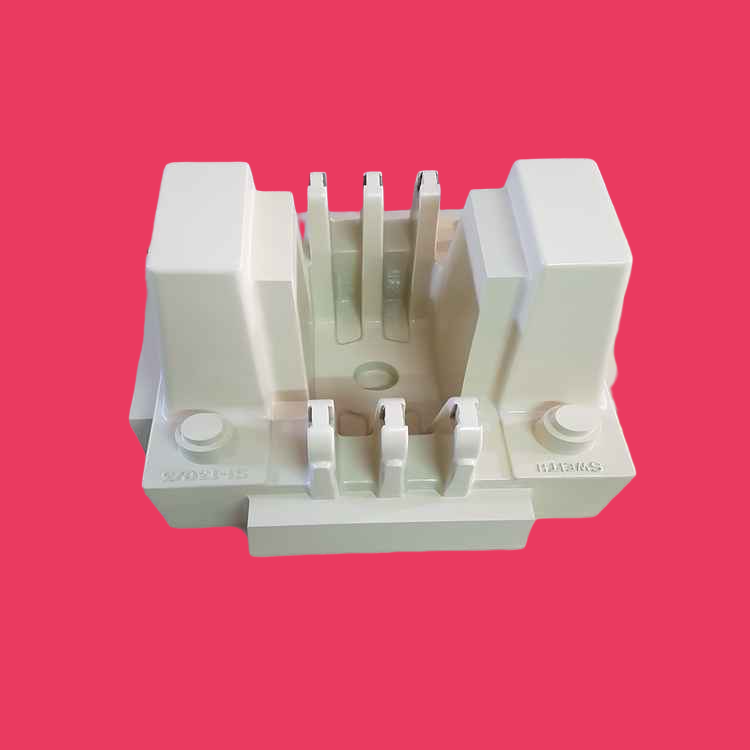

Pattern for Die Height Platen

- Made for Injection Moulding Machine Manufacturer to produce Die Height Casting from S.G. Iron Grade Material.

- Casting Weight - 900 Kgs.

- Base Material of Pattern - TEAK WOOD & Ply Wood

- Size of Pattern - 1100 x 900 x 750 mm.

- Lead time of Manufacturing - 2 Weeks

Core box of Pattern for Jaw Stock

- Made for Heavy Machinery Manufacturer to produce Base Casting from S.G. Iron Grade Material.

- Casting Weight - 2500 Kgs.

- Base Material of Pattern - TEAK WOOD.

- Size of Pattern - 2500 x 1200 x 300 mm.

- Lead time of Manufacturing - 4 Weeks

Pattern for Butterfly Valve

- Made for Casting Manufacturer to produce Valve Body Casting from S.G. Iron Grade Material.

- Casting Weight - 9000 Kgs.

- Base Material of Pattern - TEAK WOOD.

- Size of Pattern - Ø3500 x 800 mm.

- Lead time of Manufacturing - 6 Weeks

VALUE ADDITION

We provide Value addition to our customers by use of Metal Sections on Wooden Pattern and convert the ordinary Wooden Pattern in Composite Pattern.

This will give benefits like.

1. Easy Stripping from Mold, which convert into reduced Molding Labour cost.

2. Less Friction of Pattern with Mold walls which will convert in less sand fall in Mold, and ultimately reduced rejection of final component.

3. Good finish of As Cast faces, hence Eye Catching Aesthetic look.

4. Pattern achieves long Working life.